Moving grain is akin to quicksand. You can be caught knee-deep in its suction within four seconds. Self-escape from grain entrapment is impossible at this point.

Let that sink in – four seconds before you can’t save yourself.

Even with help, escape is unlikely without proper safety equipment and training. By the time you’re waist deep in flowing grain, it takes 600 pounds, plus your body weight, of force to free you. By chest deep, the pressure of the grain is too great to breathe, and you can asphyxiate even if your head is free.

Total grain engulfment takes a mere 20 seconds. Almost no one survives engulfment.

Yet, across the United States, grain entrapment is on the rise when other farm accidents are not.

Why?

Even though farmers like you are well aware of the hazards of grain entrapment, modern farming presents new risks. Grain storage bins are larger than ever, and the newest grain moving equipment is capable of moving more grain, faster. Record harvests and longer grain storage times add to the problem.

The perceived invincibility of youth, and the complacency of age also play roles when you consider most entrapment victims are under age 17, and over 55. Young victims tend to think nothing bad will ever happen to them. Older farmers and workers have been inside their bins enough times to have a false sense of security.

Three Common Risks for Grain Entrapment

One common risk for grain entrapment is being inside a grain bin while grain-unloading equipment is switched on. Out of condition grain that has created a deadly bridge can cause a high risk breakthrough. Dislodging a vertical wall of spoiled grain poses yet another threat inside grain bins.

Active Grain Flow

Nearly 80% of grain entrapment incidents happen when grain is in motion. As an auger pulls grain out from the bottom, it creates a funnel that pulls you into the grain. Considering a common on-farm grain bin has a 30,000-bushel capacity, and an adult weighs about two bushels – it’s problematic. Even operating a grain vacuum inside the bin can cause you to be pulled into the flow of grain. Struggling to maneuver the vacuum, or falling can also trigger a grain avalanche that buries you.

Spoiled Grain Bridge

When grain goes out of condition, it can form a hard crusted layer of spoiled grain across the surface. The seemingly sturdy surface may actually be a dangerous bridge hiding an open cavity of air below. You can fall in while standing on the unstable bridge of crusted grain when it breaks. It only takes seconds before the heavy chunks of grain crash down around you and shifting grain completely submerges you.

Vertical Grain Avalanche

Besides forming a dangerous bridge, out of condition grain can also stick to the vertical sidewall of a bin. When you try to loosen it, particularly from below, you risk the whole wall of grain collapsing on you. Heavy chunks of crusted grain can cause traumatic injuries, as well as release an avalanche of grain that buries you.

The example below demonstrates three common entrapment hazards: a flowing grain funnel, grain bridge collapse, and vertical grain wall collapse.

Photo: Great Plains Center for Agricultural Health

How to Prevent Grain Entrapment

According to Dr. Bill Field of Purdue University, “There is a direct correlation between out of condition grain and grain entrapment.” When grain becomes spoiled, farmers who enter bins to address problems created by spoilage can become entrapped and submerged inside.

Grain entrapment most commonly results from someone entering a bin to loosen crusted, spoiled, or frozen grain during the running of unloading equipment. When chunks of spoiled grain clog conveyors and augers, it’s natural to want to go in and unclog them.

As the saying goes, ‘an ounce of prevention is worth a pound of cure.’ The best prevention is to set a goal of never entering a grain bin in the first place. Rather than physically entering the grain bin to manage spoiled grain after the fact, keep stored grain healthy. The best way to do this is by monitoring your grain’s temperature with grain-temperature monitoring cables inside your bins.

If you must go into a grain bin, you should always have a three-person team. One person who goes into the bin with a safety harness, another person who monitors from the outside, and a third person who goes for help, if necessary. Ideally, everyone is trained, there is a rescue plan, all unloading equipment is off, and air quality is tested first.

Stay Out of the Bin with Healthy Grain

Keeping grain in good condition helps prevent entrapment and other hazards associated with entering your grain bin. It’s a simple, cost-effective solution that saves lives – maybe even yours.

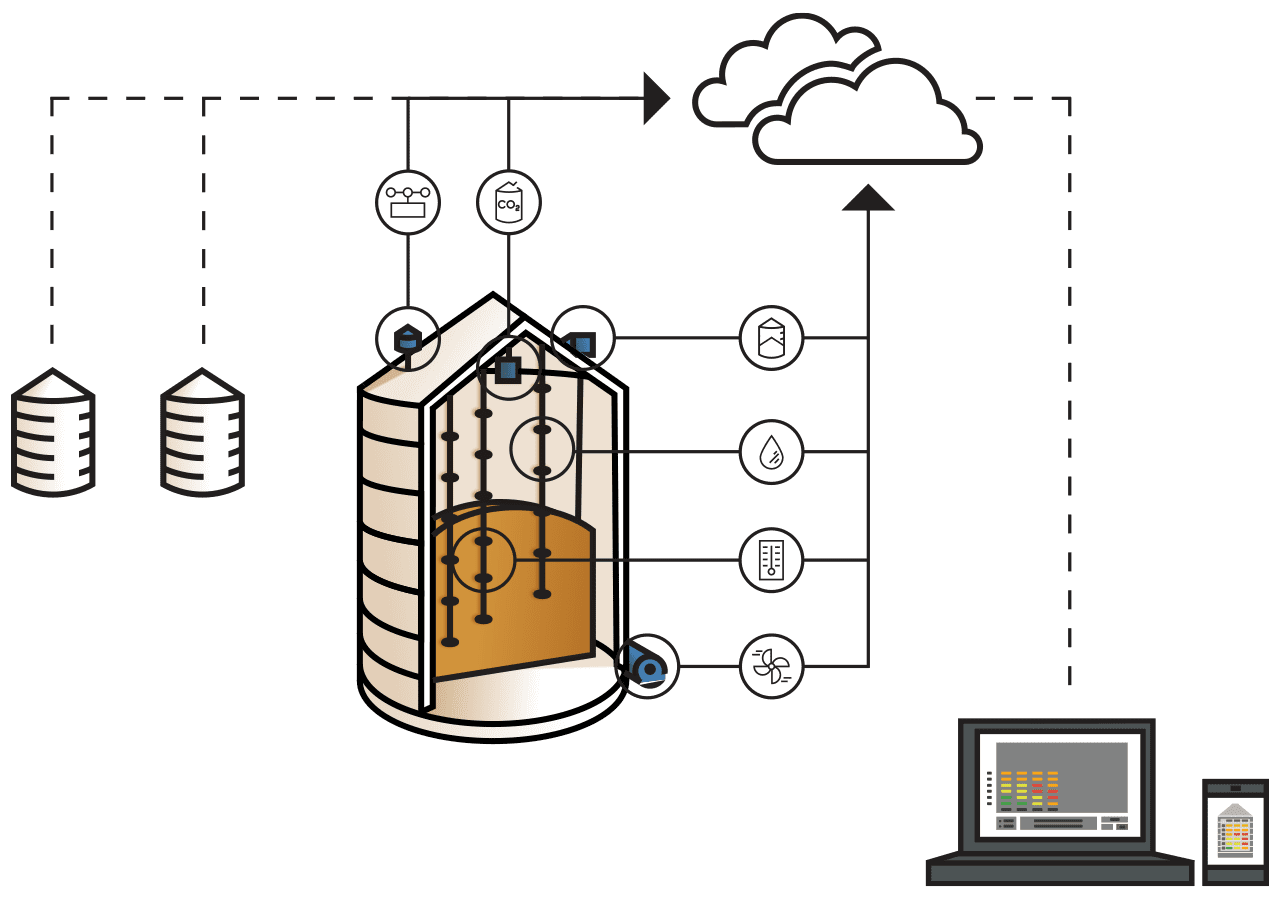

Grain temperature monitoring cables, whether connected to portable devices or remote systems, detect slight changes in grain condition in real-time. They allow you to read grain temperatures from outside the bin, or even remotely. When grain begins to go bad, it emits heat. Therefore, monitoring trending temperatures identifies any risk of grain spoiling as a result of humidity, heat, bug infestation, fungus, mold, or rotten kernels. All these problems can be avoided or solved by managing your grain’s temperature.

Grain temperature management does even more than keep you and your family safe from entrapment. It also increases the length of grain storage time by deterring spoilage, which leads to market flexibility and bigger profits. When you know your grain’s temperature, you can manage your bin fans more efficiently, cutting utility costs.

Tri-States Grain Conditioning has been helping farmers manage the condition of their stored grain for decades. Their user-friendly technology lets you easily monitor stored grain from anywhere 24/7 with a mobile app on your smartphone. The GrainTrac system not only provides temperature readings, but also gives the current volume of the grain in a bin, and how long it’s been stored.

You can avoid the risks of grain entrapment on your farm, plus enjoy the benefits of healthy grain with TSGC grain temperature monitoring systems. Ask us about options here, live chat with us here, or call us at 800 438 8367.

Remember, grain entrapment isn’t limited to grain bins. Entrapment and engulfment can occur wherever there is a large amount of grain, including trucks and piles. To learn more about grain entrapment and rescue, watch this short video.

(Sources: Great Plains Center for Agricultural Health, University of Iowa. Video is a collaboration of National Corn Growers Association and National Grain and Feed Foundation)

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and smart farming.