Between carrying more grain into the new crop year and another year of record crop size, fall brings a predictable grain storage shortage…again.

The USDA is predicting historic corn and soybean harvests this year with soybeans at 4.7 billion bushels and corn at 14.8 billion bushels. These are the largest and second-largest harvests respectively in U.S. history. The problem is that grain storage capacity, even though it’s increased by 30%, isn’t keeping up with storage needs. We’re having another grain storage shortage like last year where grain piles dotted the landscape at harvest.

Expanding your on-farm grain storage capacity can have a number of benefits to your overall farm management and marketing plan. However, it’s not an easy decision to expand on-farm grain storage. Here’s why you should at least think about it.

Market Signals

Right now the markets are signaling farmers to store their grain. NDSU Extension Crops Marketing Economist, Frayne Olson, advises farmers to store soybeans at harvest. With many elevators not accepting soybeans, and no incentive for farmers to sell at harvest, on-farm storage is an important alternative.

Olson warns farmers not to look at the storage shortage as a temporary problem, “This is something that will likely take many months to fix, even if the tariffs were removed.”

More Efficient Harvests

Farm operations whose crop yields have been steady, or even increasing, would benefit from their own on-farm storage. You can dry and store grain yourself longer and cheaper than using an elevator. You’ll improve your harvest efficiency keeping everything on-farm, and you won’t have to commit to bushel delivery at harvest.

Shortage of Elevator Storage

Due to trade tariffs and low prices, some elevators have at least a quarter of their capacity already being used by leftover grain. Record yields in both soybeans and corn this year will stress available storage even more. Licensed elevators are permitted in Iowa to store grain in covered piles temporarily. In other crop-producing states, like Indiana, licensed facilities are making applications to do the same. Some may reach the point of not accepting more grain.

Lower drying/shrinking costs

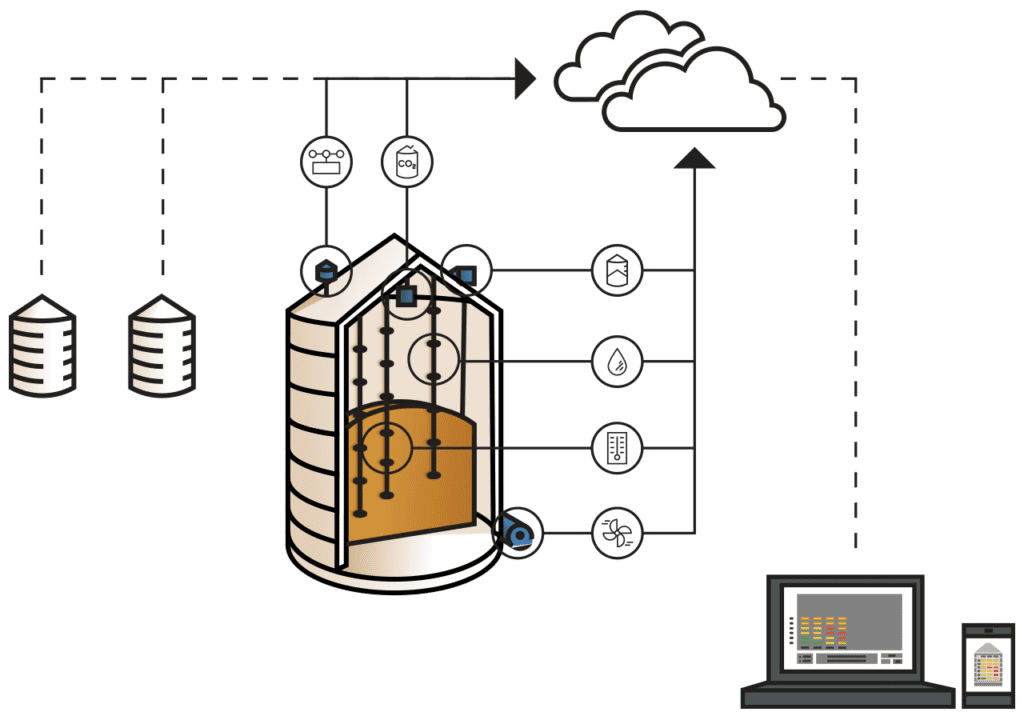

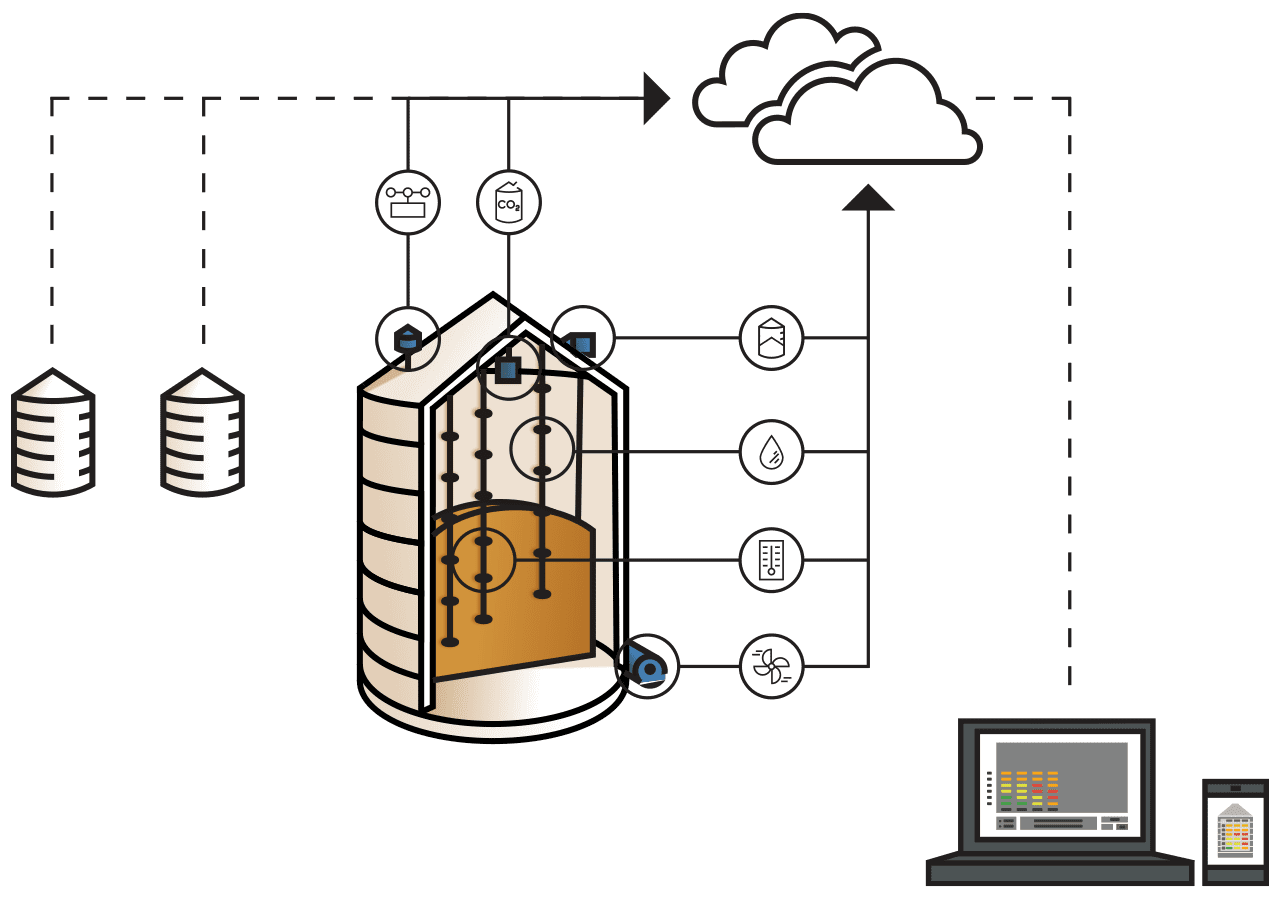

Farmers can usually dry wet corn and soybean bushels cheaper than having it done at a commercial elevator. With grain temperature monitoring cables installed in bins, it’s easy to get accurate temperature data to make fan decisions. Overusing fans leads to too much grain shrink and higher energy costs, both of which affect your bottom line.

Charles Hurburgh, ISU Professor of Agricultural and Biosystems Engineering, warns, “A good portion of the crop will need to be kept over a year, so what you do now makes all the difference.” He advises quickly drying corn to 14% grain moisture, and to 12% grain moisture for soybeans before storing long-term.

Better Grain Quality

Price is an important factor when considering grain storage, but grain quality is too. Alternatives to storing grain in bins properly fitted with grain temperature monitoring cables should be considered temporary solutions. You can’t monitor grain temperature or moisture movement in storage bags, which opens the door to all the problems heat and moisture cause, including insect infestation and mold.

Being able to store grain in a clean, well-prepared bin with temperature monitoring cables allows you to monitor the quality of your stored grain. The better the condition of your grain at harvest, and the better the storage environment, the longer you can store your grain. The higher quality your grain is when you are ready to sell, the better price you’ll get.

Market Flexibility

When you have your own on-farm grain storage, you can spread your cash sales over months when it’s the most opportune time for your farm’s operation. You aren’t constrained by space and time, and you aren’t at the mercy of the market.

ISU Extension Economist, Chad Hart, is encouraging farmers to look for ways of protecting themselves from the current depressed crop prices. Right now, it makes sense to delay grain sales until traditionally better spring markets, particularly if trade talks with China and Mexico make progress.

These marketing decisions are made easier when you have your own storage facilities.

Where to Go From Here

When harvest season is over and you’re planning for next year, reflect on this year’s harvest experience as your guide. Here are some things to look back on for future planning.

If harvest moisture levels were a few points higher, would your dryer have been able to handle the elevated need? Would you have had the necessary propane supply at a reasonable price?

If the nearest elevator wouldn’t have accepted your grain, would you have had the transportation capacity to deliver grain farther away while still harvesting?

If there wasn’t enough permanent storage on hand to keep from having to resort to less sustainable grain piles and other temporary storage, would you have suffered losses from spoilage? Or, would you have been at the mercy of the market?

Following a string of bigger crops every year for the last few years, there’s no reason to think it won’t continue next year. So the question is, if you struggled with crop management this year, what will you do differently to handle another big crop next year?

Taking Control of Your Grain Storage Management

The best way to ensure stored grain quality is with temperature monitoring cables in your bins. And the best time to install them is when you’re building new bins on your farm. You can also add monitoring cables to existing bins to make sure no grain goes unmonitored, it just makes sense to install the cables as the bin is being built.

Tri-States Grain Conditioning will work with your bin dealer to get you set up with a grain temperature monitoring system in minimal time. If you’ve decided to take control of your grain quality on-farm, we can also help you set up cables in existing bins the right way.

Together, we can solve a potential grain storage shortage on your farm.

Call us at 800 438 8367, contact us here, or live chat with us to ask about the right grain temperature monitoring system for your new or existing on-farm storage facilities.

(Sources: Iowa State University Extension and Outreach and North Dakota State University Extension)

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and smart farming.