Where you store your grain can be as important as when you harvest it. Can on-farm corn storage help save money in the long-term? Or is it just too expensive compared to commercial options?

The numbers don’t lie. Based on information from several studies, on-farm grain storage is just the better bet. Why is that the case? Let’s take a look.

Save Money in the Long Run

According to the U.S. Department of Agriculture, corn exports are down 11 percent from 2018. That problem leaves farmers with tons of extra grain still sitting from last year and no room for the crop coming this fall. Traditionally, farmers make the argument for commercial or rented storage. In theory, up-front costs are lower, since you’re paying to rent a space rather than building storage. Those rental fees at a commercial lot are based on the number of bushels stored by day or month. But there are still some costs to consider.

“Higher transportation and labor costs may be incurred if the rented storage is located a significant distance from the producer’s home base,” Iowa State University’s Cooperative Extension says in a Dec. 2018 report. “There also may be a handling fee if grain is withdrawn from the condominium storage.”

Now that’s not to say on-farm corn storage is cheap. The costs are structured differently however. The major cost for on-site storage is construction, but that “investment can be spread over the life of the bin, in the form of depreciation and interest on the capital invested,” Iowa State’s report says.

If storage is on-site, you don’t have to deal with rental fees or any other type of fees. So over the 25-30 years of a storage silo’s useful life, that one-time construction investment is worth it. You also save the fuel costs associated with delivering grain to a commercial silo.

Control Grain Condition

Another problem with commercial storage is temperature monitoring. It’s important to monitor grain temperature on a weekly basis, especially after the harvest season. Otherwise, you run the risk of mold, mildew and other issues building up. That damages your crop and leads to a lower price once you’re ready to sell. Depending on what moisture level your corn is delivered at, you could risk some drying and shrinkage as well.

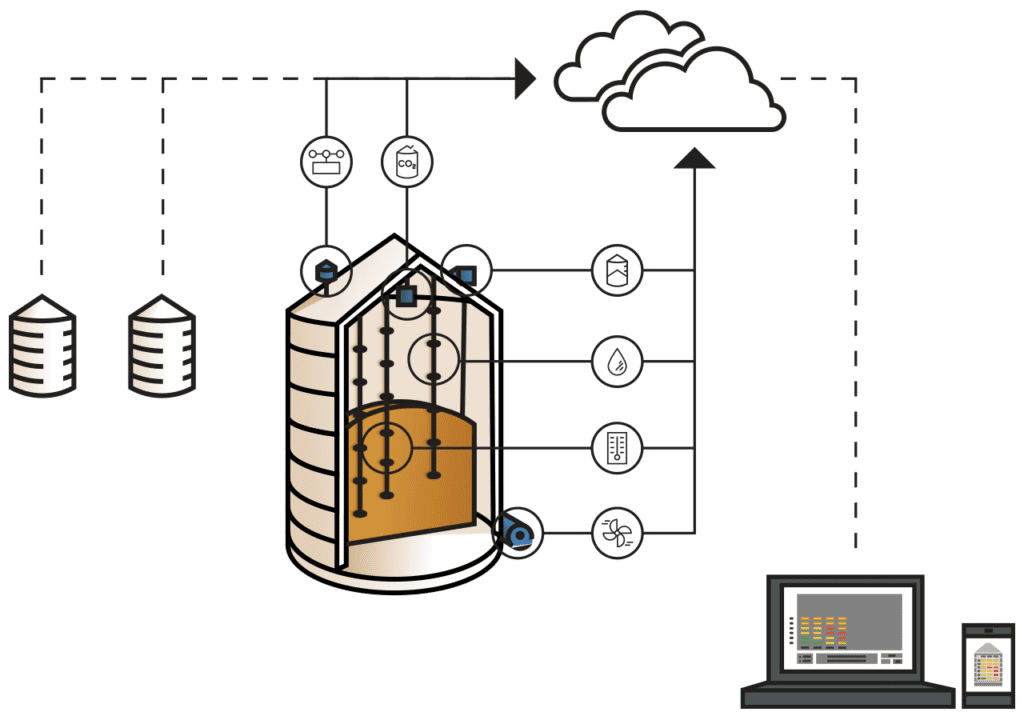

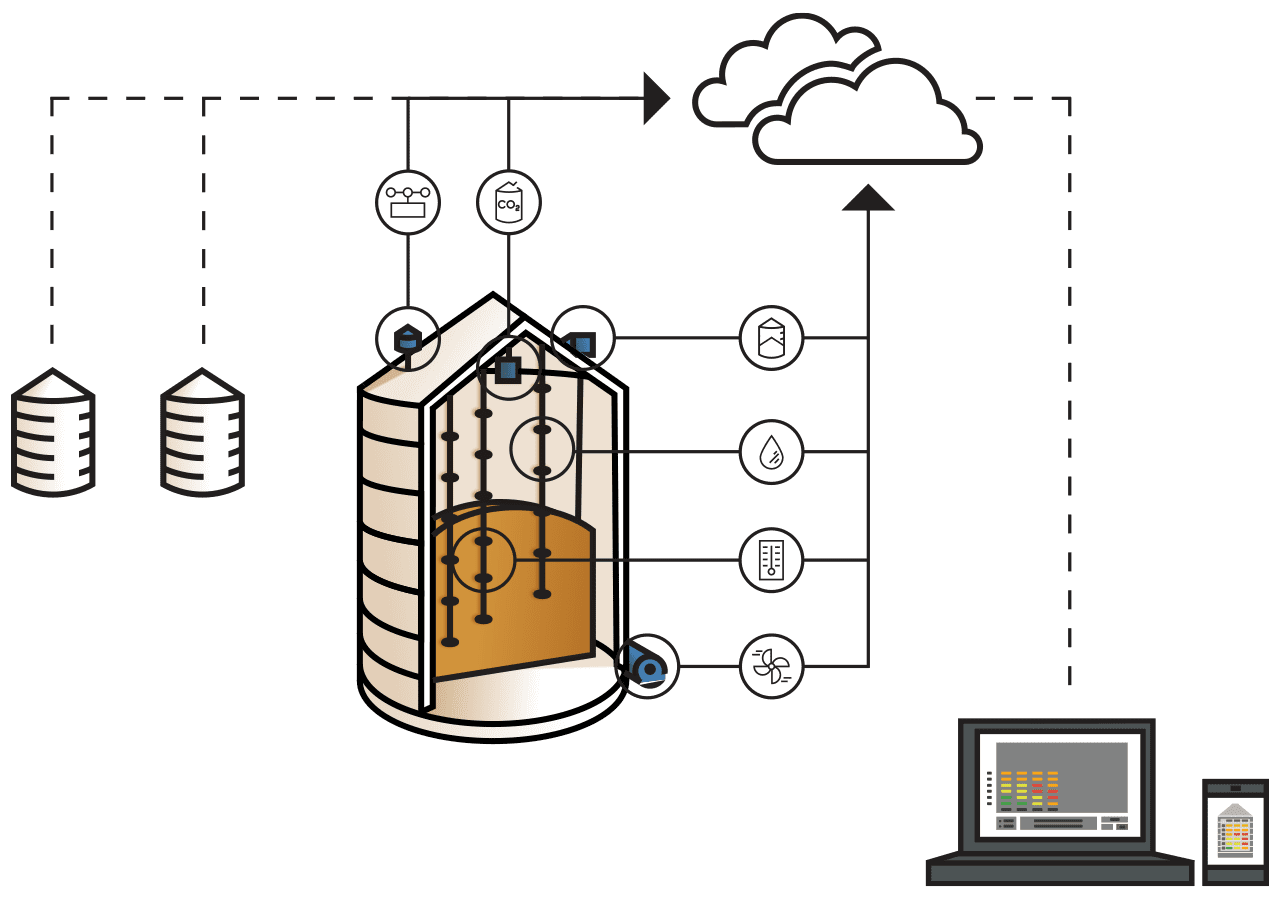

Instead, if you have all of your corn on-site, you can control the condition of your grain much more easily. Knowing the temperature of the corn doesn’t just prevent mold. You can stop insect damage, extend storage time, and save on electric bills. How do you manage that last part? Well, you can set up the system to run fans only until the corn cools down. You don’t even have to check the conditions in person. Remote systems can handle that, so you can check temperatures and make decisions from your phone or laptop.

Controlling temperature is important. On average, a 2018 Purdue University report says corn temperatures range from 50 to 80 degrees Fahrenheit at storage time. You want to make sure the corn stays at 55 degrees or lower. Having on-farm corn storage gives you the most grain quality control.

Harvest Faster with On-Farm Corn Storage

One of the biggest costs of storing corn commercially is time. Everyone wants to wrap up a harvest quickly. If you store corn off-site, then you have to deal with both the costs and time involved with traveling there. A 2018 University of Arkansas report found that keeping grain off-site costs an extra one to two hours of work.

Also, once you commit to a specific commercial storage site, you’re basically locked into selling the corn to that company as well. Even if another group offers better prices, it’s not worth moving the corn. You would have to travel to the storage site, reload the corn, and take it to this third location. All of this increases fuel costs.

A 2018 U.S. Department of Agriculture report found farmers in the U.S. spent a total of $12 billion on fuel. Out of that, diesel accounts for 63.3 percent or $7.6 billion, up 2.7 percent from the year before. Gasoline expenses are up 4.8 percent, to $2.2 billion, while LP gas is up 22.4 percent to $1.4 billion. It’s never a bad idea to cut back on cost. You’re saving both time and money with on-farm corn storage.

Avoid Grain Shrink with Fan Control

Finally, if you store corn on your farm, studies show you’ll have a larger crop. Corn shrink is defined as the loss of weight caused by drying and handling the grain. According to a 2018 University of Minnesota report, a commercial site sees 1.5 percent of the crop shrink during storage. By comparison, 1.25 percent of corn crop shrinks on a farm, so you save 0.25 percent. Let’s say you get $3 per bushel and bring in 150,000 bushels this year. If you store on the farm, you save $5,625 per year in shrinkage over commercial storage.

Do you know what’s happening inside your bins at this very moment? Is there a hot spot waiting to grow into a disaster? Access this important data 24/7 with remote grain monitoring. Ask an expert how to get started saving money and protecting your greatest asset – your grain.

If you’re ready to talk on-farm grain storage strategy, contact us and we’ll lend our experience of working with thousands of farmers around the world for over 35 years.