As we move through summer, it’s time to start thinking about grain storage. How big will this year’s crop be? Do we have enough space set aside? More than that, do we have the right tools to prevent rot and waste? That last question can be the most perplexing, as some farmers wonder why they need to monitor grain. After all, their father and grandfather didn’t, so why should they? There are actually three big reasons why it’s more important to monitor grain today than ever before.

Discover What You Don’t Know

Mother Nature hasn’t been kind to American farmers in 2019. From March to July, the U.S. Department of Agriculture said farmers lost nearly 6 million acres of corn and soybeans due to rainy conditions.

Those losses mean it’s critical to keep stored grain in prime condition to sell. As we’ve mentioned before, grain monitoring is the best way to do that. But while grain monitoring is an option, what makes it the best idea for farmers?

I often get that question over the phone, “Why should I monitor my grain? Why should I invest that money?”

First off, you need to monitor your grain to discover what you don’t know when you aren’t monitoring your grain. People will tell me, “Well, I have a good nose, so I’ll climb up there and smell my grain, and I can smell it when it gets too hot.’”

You may have a good nose, but by the time you can smell grain spoilage, you’ve already lost a lot of money. That’s because grain bins are larger than they used to be. In years past, bins held a crop as small as 1,000 bushels, but now they hold up to 1.9 million bushels. With the larger bins, by the time you smell overheated grain, you’ve lost 500 to 1,000 bushels. That’s a lot of money to throw away.

Save Money with Data-Based Decisions

Second, grain monitoring can save you money in a number of ways. With farm expenses rising, it’s critical to cut costs in any possible way. The USDA’s 2018 Farm Production Expenditures Report shows that in 2017, expenses for American farmers came to $359.8 billion. That’s an increase of $12.9 billion from 2016, when the total expenses came to $346.9 billion. What’s causing the extra costs? The cost of farm services, livestock, and labor are all on the rise, along with fuel.

With that in mind, just think about one question. How long do you run your fans in the fall? After you put grain in the bins, do you run it for a day? A week? Two weeks? How can you tell when it’s time to cut off the fans?

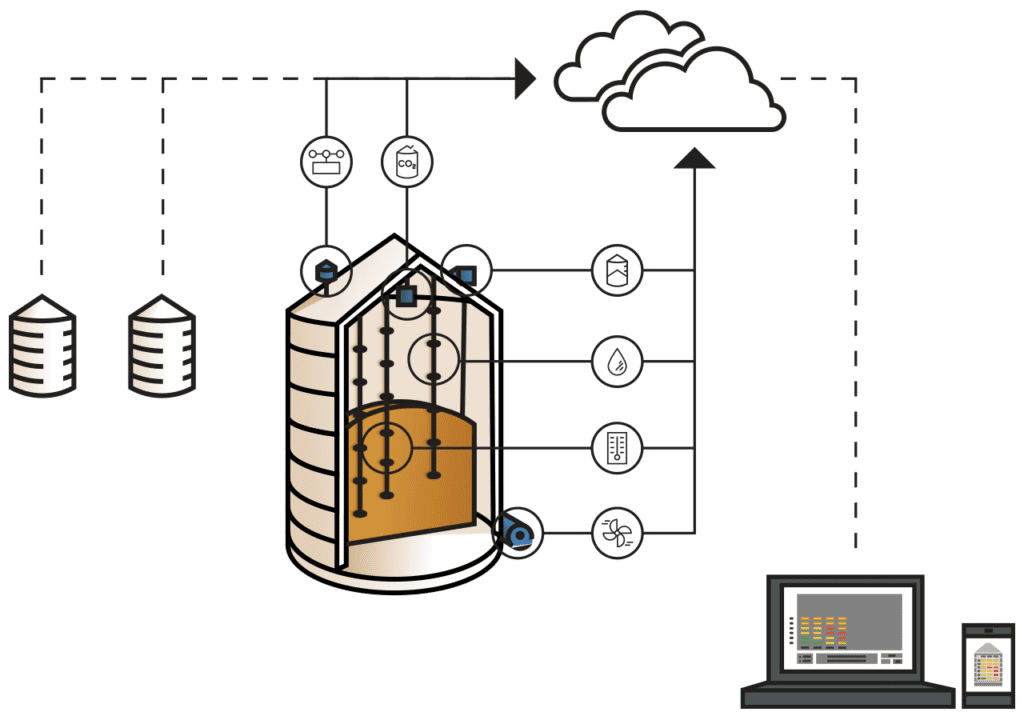

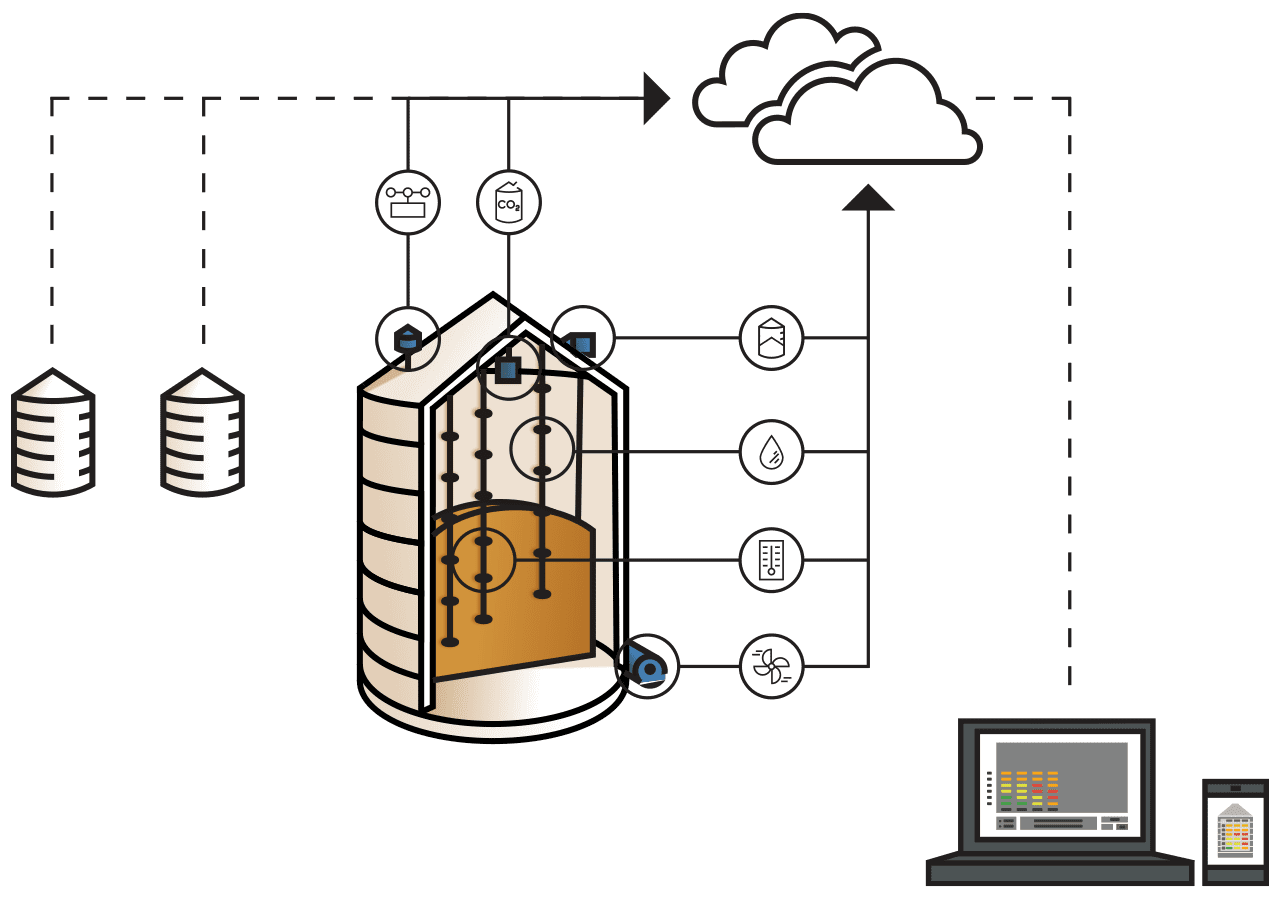

You don’t know how long to run your fans unless you’re monitoring that grain. With the grain temperature cables centered in the bin, you can watch that cool front rise up through the grain, and as soon as the grain is cool, shut the fans off, leave them off, and you’re done.

If you leave the fans running longer than you need to, you’re not just dealing with a bigger electric bill. You also run the risk of overdrying your grain. That means when you take the grain to the elevator, there’s a good chance you’ll get docked for shrink, because the grain is too dry.

Claim Your Peace of Mind

Finally, grain monitoring offers you peace of mind. By investing one cent per bushel, you can monitor 15 percent of your grain, essentially that center mass in your bin. By investing three cents per bushel, you can monitor 50 percent of the grain that is in your grain bin. If you spend 4 cents per bushel, you can monitor 100 percent of the grain that’s stored.

A 2018 report from Purdue University’s Cooperative Extension Service echoed that statement, pointing out that “more dried grain goes out of condition because grain temperatures are not controlled than for any other reason.”

With grain, quality is key. The higher the quality, the better the price when you’re ready to sell. Now, you can’t improve the quality of your grain after the harvest. At this point, it’s fully mature. But you can protect it from deteriorating by controlling the temperature. If the air temperature isn’t controlled, moisture can build up and cause the grain to spoil.

Good peace of mind starts with a smart investment, but it ends with knowing what’s happening inside your bin. It gives you peace of mind. That’s something that doesn’t have a price tag.

Call Tri-States Grain Conditioning at 800 438 8367, contact us here, or live chat with us here to ask about grain temperature monitoring for stored grain. Rediscover your peace of mind.

Join over 20,000 other farmers who follow us on Facebook. We discuss a variety of farming topics including agribusiness, agritech, and grain temperature monitoring.