By 2050, the global population is expected to reach ten billion. This boom in population growth requires food production to increase by more than 55 percent compared to 2010’s levels. However, studies have cautioned that farming production will struggle to meet the additional need for food across the globe. Poor crop yields due to soil-nutrient deficiencies and soil degradation are just two of the challenges agriculture production faces. Increased pestilence, extreme weather events, and postharvest grain loss will prove most detrimental to supplying demand.

Let’s explore postharvest grain loss at the storage level of the food production supply chain, then examine the solutions agriculture experts suggest for better storage practices. These solutions increase the chances of meeting the global food demand by preventing unnecessary postharvest grain loss.

Postharvest Grain Loss: How Much is Lost at the Storage Level

Postharvest losses are seen across most crops including vegetables, pulses, fruits, and grains. However, the latter leads the pack in losses, specifically cereal grains. One study estimated that twenty percent of global grain production was lost in 2018 alone. These are especially jarring statistics when considering cereal grains make up 70% of calories consumed by the global population.

Studies have shown as much as 60% of grains can be lost at the storage level exclusively due to technical inefficiency. Conversely, the use of scientific storage methods can reduce these losses to as low as 1%.

The severity of postharvest grain loss is dependent on several factors including climate, pervasiveness of pests, and geographic location. For example, in Peru, most of the grain loss is due to their drying technique. Nearly all their farmers dry their crops directly on the ground in their fields. This exposes them to birds, rodents, and insects accounting for postharvest grain losses of between 15-27 percent. In Thailand, the largest waste occurs during the handling and storage of their cereal grain.

Most postharvest grain losses occur in developing nations; however, losses occur in developed nations as well. There is no region of the world where postharvest grain loss isn’t an issue. For this reason, many regions have created aggressive targets to reduce waste.

How can we reduce postharvest grain loss with best storage practices?

Reducing Postharvest Grain Losses Across the Globe

There are several technologies and approaches – both traditional and advanced – that can be used to reduce postharvest grain loss. Let’s focus on reducing grain loss at the storage level. Although, it’s important to note that overall postharvest grain loss will require changes at every level of the supply chain. Cost-saving techniques need to be implemented at the harvest, threshing, processing, transport, and marketing levels as well.

Grain loss due to humidity and temperature is one of the primary areas to address to reduce waste. Properly regulating the moisture and temperature of stored grain is paramount since most spoilage occurs at the storage stage. One way of addressing humidity-related postharvest grain loss is by implementing a worldwide “dry chain” described by Dr. Kent Bradford. The system would act much like the “cold chain” of produce works which keeps produce fresh with continuous refrigeration.

The “dry chain” would rely on an “initial dehydration of grain to levels that would prevent fungal growth, followed by storage in moisture-proof containers” according to Bradford. It would include low-cost practical solutions like disposable paper swabs used to test grain humidity instantly. Additionally, Bradford advocates the implementation of oxygen-impermeable “dry bags,” and aluminum silicate desiccant beads. The former is used to kill insects without damaging grain and the latter is used to keep a low-humidity environment.

Remote Grain Monitoring: Protecting the Global Food Supply

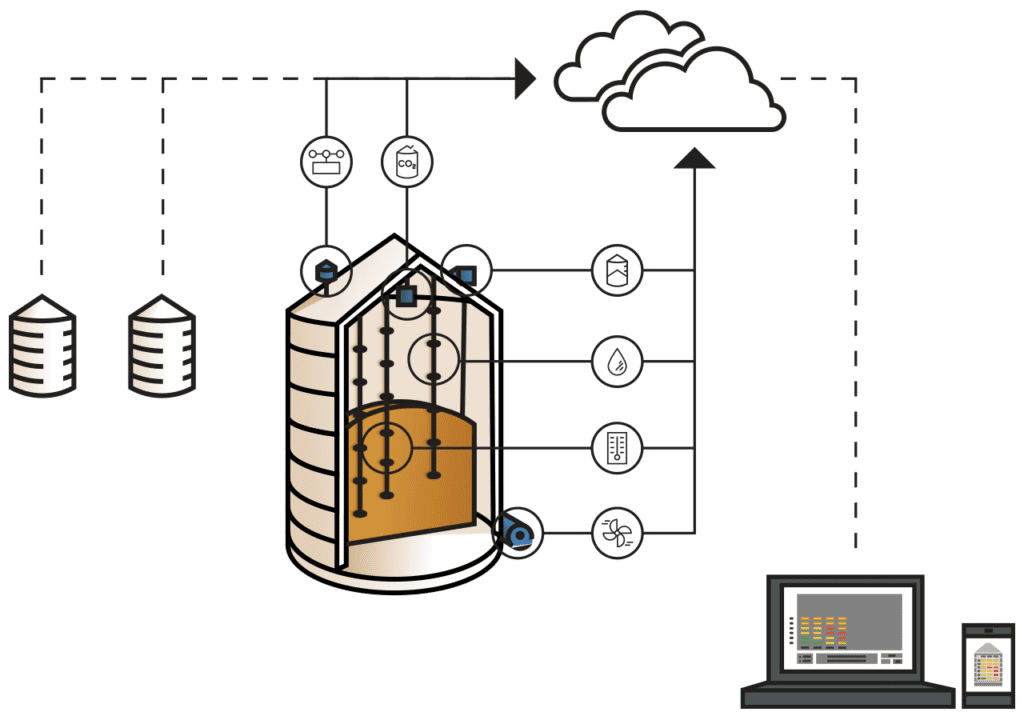

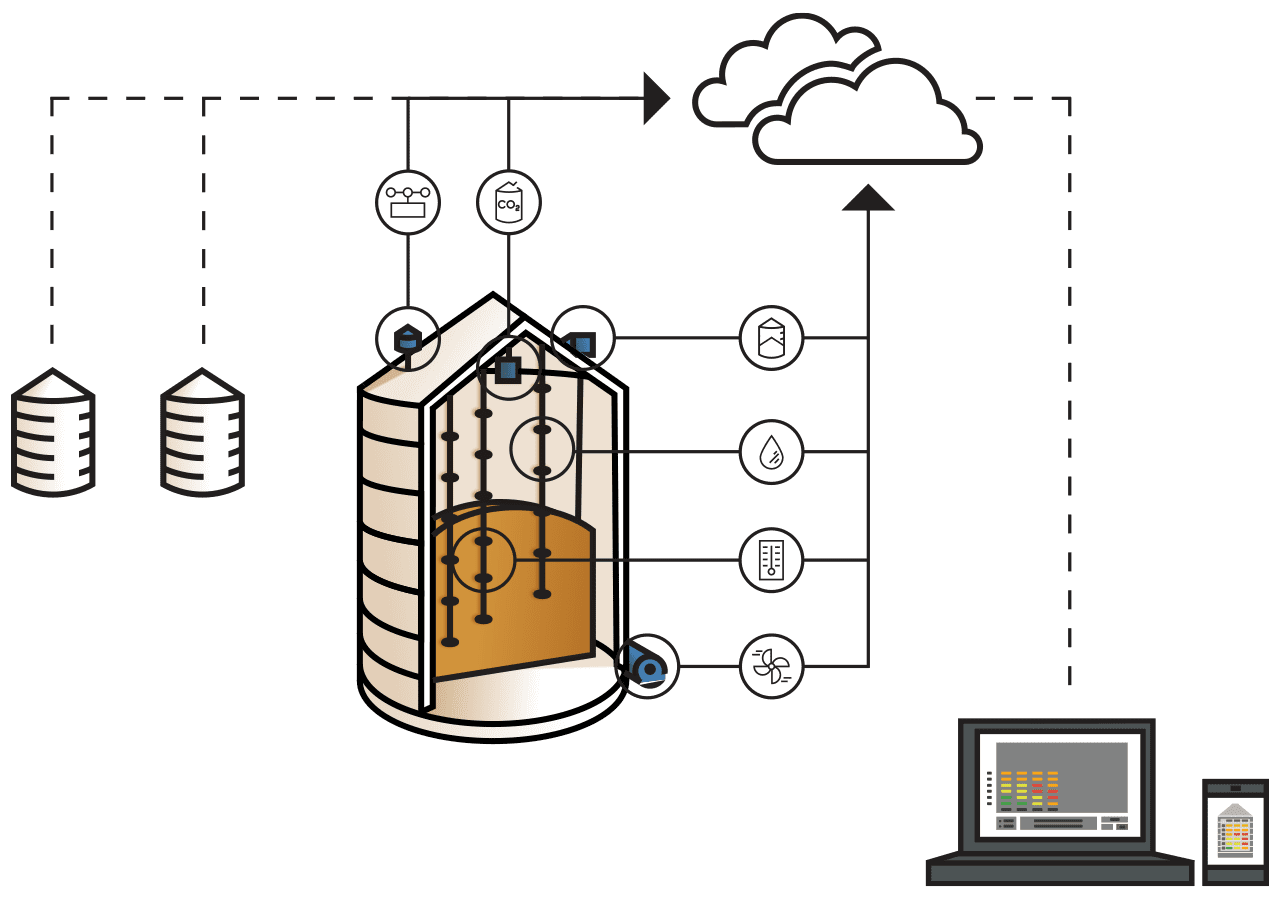

While the low-cost solutions of “dry chain” will be fundamental in reducing postharvest losses, IoT will have the biggest impact. The Internet of Things (IoT) describes smart technologies – equipment that communicates through software providing important data. For example, GrainTrac Remote Grain Monitoring systems use cable sensors inside grain bins to monitor the grain’s temperature remotely.

This smart technology allows farmers to get real-time, up-to-date information on their grain health from the palm of their hand. This technology is by far the biggest game-changer to eliminating postharvest loss due to poor storage practices. If every farm monitored their grain using this smart-technology, grain loss at the storage level could be eliminated entirely. What an impact that would make on our global food supply.

Ask us about options here, live chat with us here, or call us at 1 800 438 8367.

Follow us on Facebook where we discuss a variety of farming topics, including best grain storage practices, grain temperature monitoring, and Smart Farming.